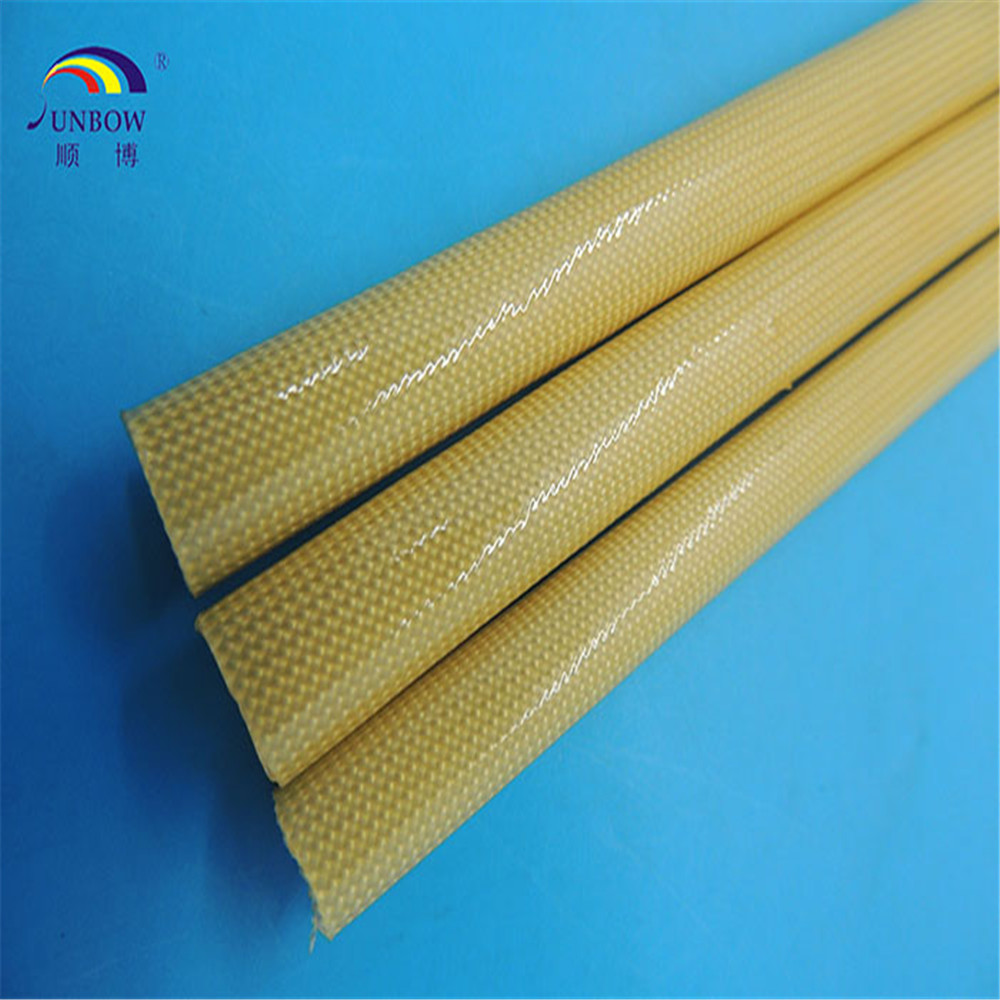

Optical Fiber Protection Heat Shrink Tube

Mode number: SBD-SWHF-F

Optical fiber protection heat shrink tube, commonly known as fiber optic pipe, scientific name: fiber fiber continuing thermal deflation Optical fiber protection heat shrink tube is designed for FTTH optical fiber -to -house engineering. The hot melting method can melt all the leather optical cables or between the leather optical cable and the single -core jump fiber in the sleeve.

Usage

Optical fiber protection heat shrink tube is widely used in the melting of communication products such as optical cable joint box, optical cable terminal box, ODF box, broadband network box, optical cable interlax box, optical cable fiber box.

Characteristics

1. shrinking temperature is low, and the hot melt speed is very fast.

2. Steel needles have greatly improved the high mechanical strength of melting, providing intensity and protection for the fiber -fiber junction. The sealing structure enables the continuity to have good temperature resistance and humidity performance.

3. The attenuation is almost zero, the signal is more stable, and the transmission speed is faster.

4. operation, reducing the danger of damage to optical fiber during installation.

Specification

Property | Standard | Test method/Standard |

Working temperature | -55℃ ~100℃ | IEC216 |

Tensile strength(MPa) | 18 | ASTM D 2671 |

Breakage Elongation(%) | 700 | ASTM D 2671 |

Density(g/cm) | 0.94 | ISO R1183D |

Vertical shrinkage rate(%) | ±5 | ASTM D 2671 |

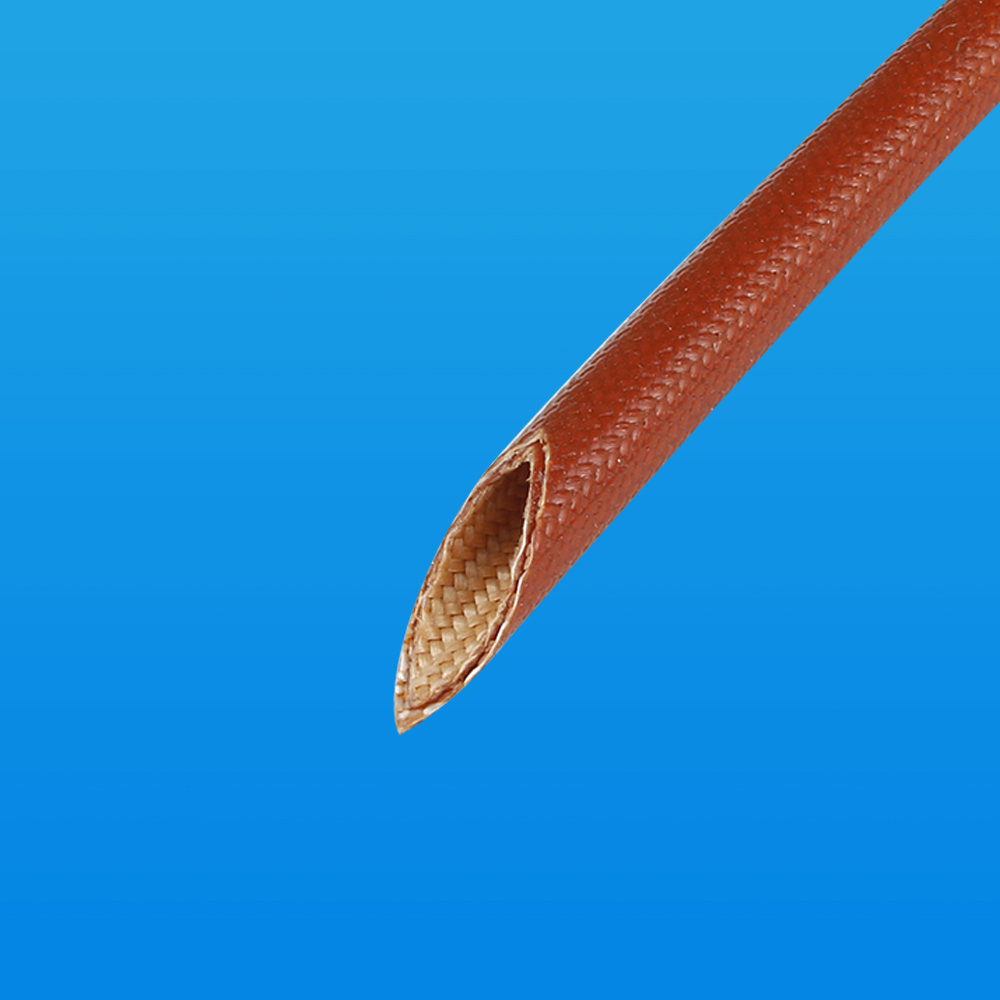

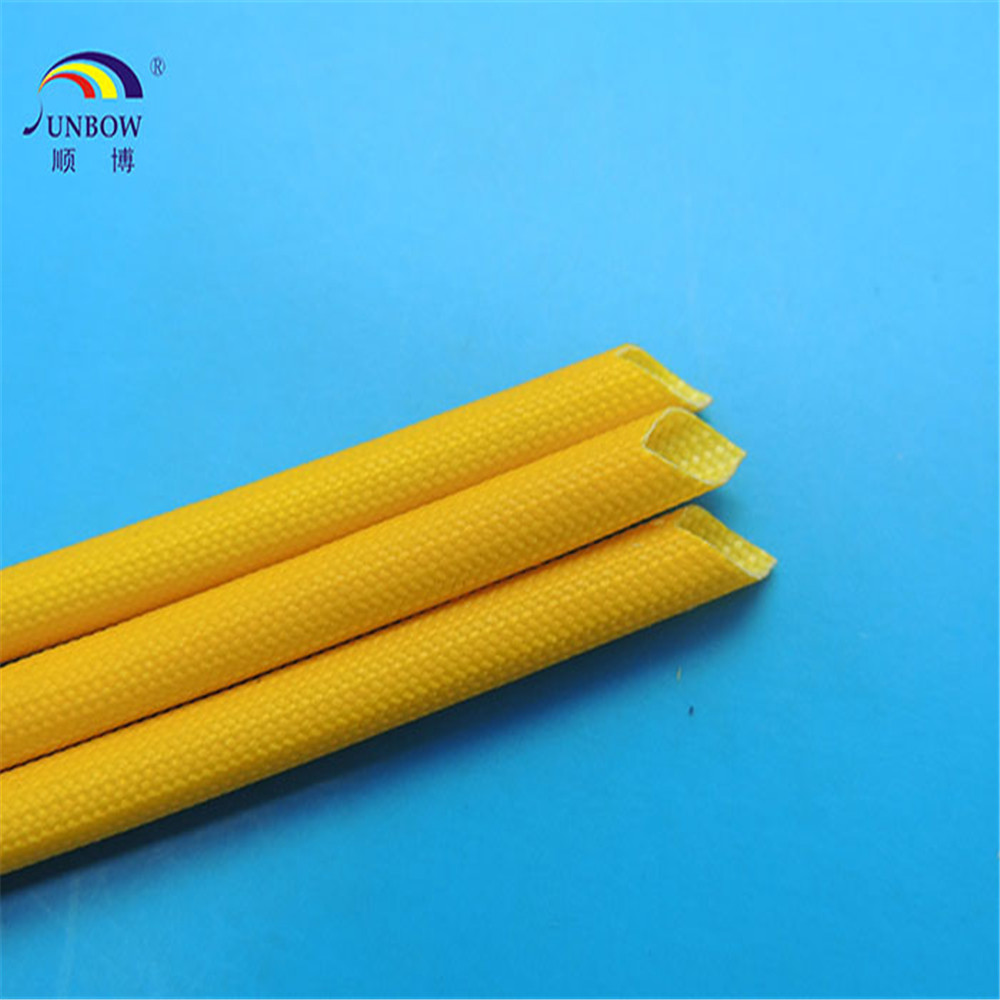

Structure

Dimension

Size | Stainless steel needle | Melting tube | OD after shrinking(mm) | Length (mm) | |

ID(d) mm | Length mm | ID(D) mm | |||

Mini optical fiber protection tube | 1.0 | 55 | 0.5 | 2.0 | 60 |

1.0 | 45 | 0.5 | 2.0 | 50 | |

1.0 | 40 | 0.5 | 2.0 | 45 | |

1.0 | 35 | 0.5 | 2.0 | 40 | |

Normal optical fiber protection tube | 1.2 | 55 | 1.3 | 2.5 | 60 |

1.2 | 45 | 1.3 | 2.5 | 50 | |

1.2 | 40 | 1.3 | 2.5 | 45 | |

1.2 | 35 | 1.3 | 2.5 | 40 | |

Max optical fiber protection tube | 1.5 | 55 | 1.5 | 3.0 | 60 |

1.5 | 50 | 1.5 | 3.0 | 55 | |

1.5 | 45 | 1.5 | 3.0 | 50 | |

1.5 | 35 | 1.5 | 3.0 | 45 | |

1.5 | 40 | 1.5 | 3.0 | 40 | |