Model number:SB-PVC

Working temperature: -30ºC~+105ºC

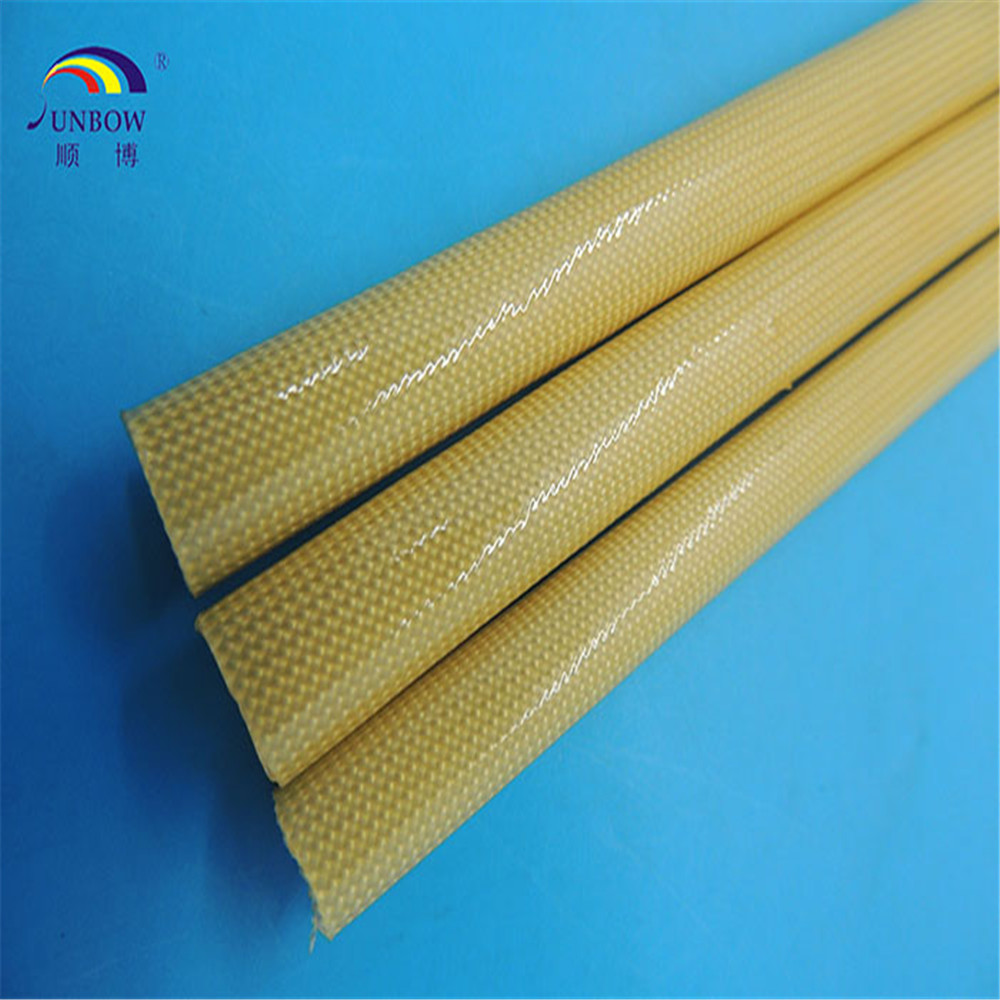

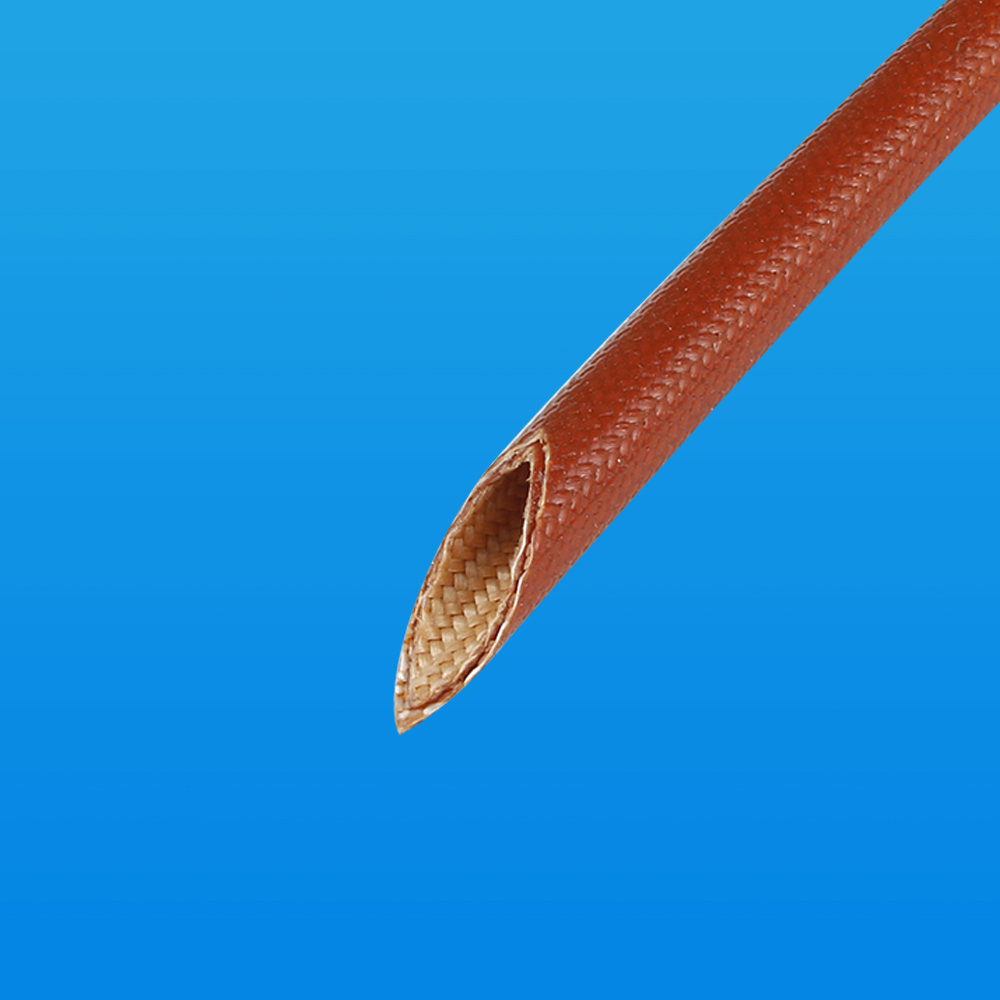

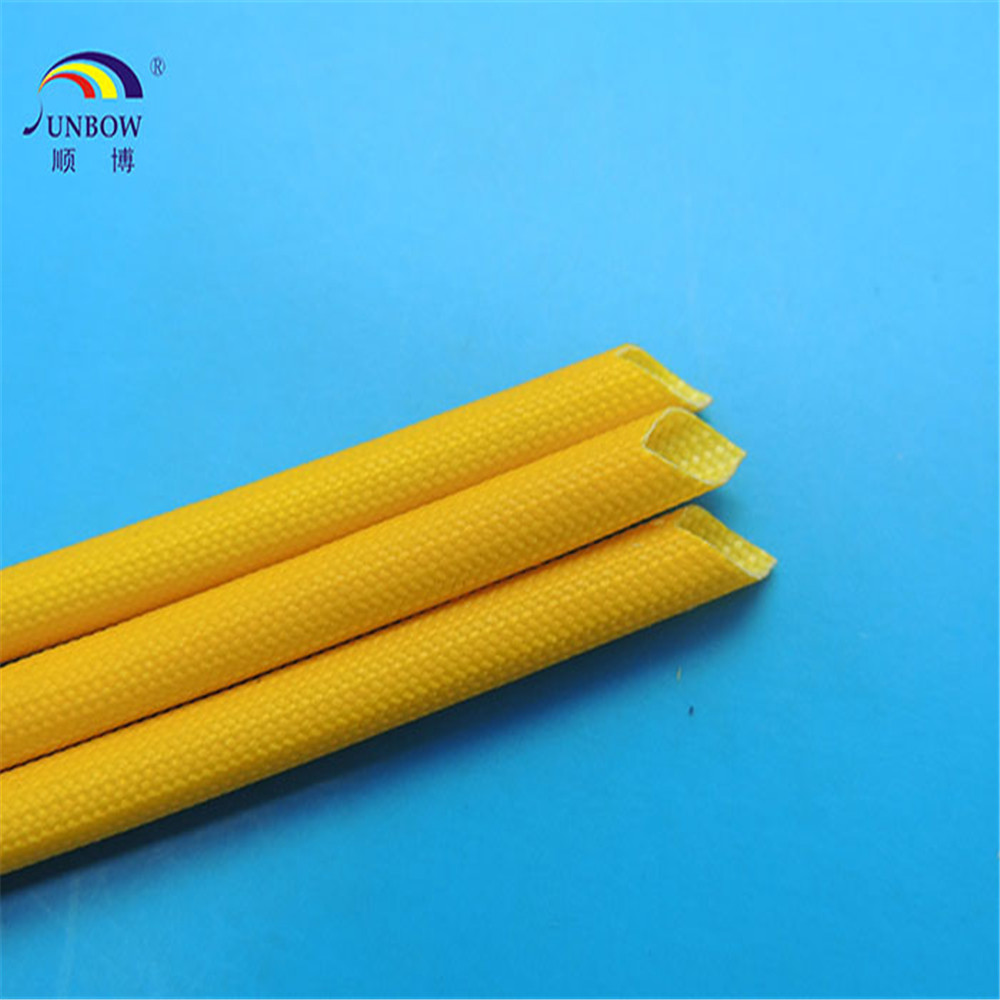

Structure

Working temperature: -30ºC~+105ºC

Structure

PVC tubing is produced by superior and environmentally friendly polyvinyl colloidal particle, after drying, extruded to tubing when heated up and liquated, then packing in rolls after cooling.

Usage

With the excellent flexibility, mechanical and dielectric capability, flame resistance performance, PVC tubing is widely used in outside insulation protection of outgoing wires of electrical appliances, transformers, electrical motors or lighting equipment, and electronic components, wire harness and etc.

Specification

Item | Unit | Test Method | Numerical Value | ||

SB-300 | SB-600 | ||||

Voltage rating | V | 300 | 600 | ||

Temperature rating | ºC | UL224 | 105 | ||

Voltage resistance | Before aging | UL224 23ºC | 2500V/60sec | ||

After aging | UL224 136ºC 168hr | 2500V/60sec | |||

Volume resistivity | Ωcm | UL224 | ≥1010 | ||

Tensile strength | Before aging | Mpa | UL224 23ºC | ≥10.4 | |

After aging | Mpa | UL224 136ºC 168hr | ≥7.3 | ||

Elongation | Before aging | % | UL224 23ºC | ≥100% | |

After aging | % | UL224 136ºC 168hr | ≥100% | ||

Flexibility | UL224 136ºC 168hr | No cracking | |||

Heat shock | UL224 180ºC 4hr | No cracking | |||

Cold bend | UL224 30ºC 1hr | No cracking | |||

Copper stability | UL224 136ºC 168hr | No corrosion | |||

Flame resistance | UL224 | VW-1 | |||

Hardness | 85A to 90A | ||||

![]() Special instruction: The PVC tubing supplied for the customers should be based upon the samples which confirmed by both sides, not restricted by the above performance index.

Special instruction: The PVC tubing supplied for the customers should be based upon the samples which confirmed by both sides, not restricted by the above performance index.

Dimension

(One)The British system series of AWG

AWG No.

|

Inner Diameter(mm)

| Wall Thickness (mm) |

Package size(m/r) | |

SB-300 | SB-600 | |||

20 | 0.85±0.1 | 0.25±0.05 | 0.40±0.05 | 500 |

19 | 0.9±0.1 | 0.30±0.05 | 0.40±0.05 | 500 |

18 | 1.0±0.15 | 0.30±0.05 | 0.45±0.05 | 500 |

17 | 1.2±0.15 | 0.30±0.05 | 0.45±0.05 | 300 |

16 | 1.3±0.15 | 0.30±0.05 | 0.45±0.05 | 300 |

AWG No.

|

Inner Diameter(mm)

| Wall Thickness (mm) | Package size(m/r) | |

SB-300 | SB-600 | |||

15 | 1.5±0.15 | 0.30±0.05 | 0.45±0.05 | 300 |

14 | 1.7±0.15 | 0.30±0.05 | 0.45±0.05 | 300 |

13 | 1.9±0.2 | 0.30±0.05 | 0.45±0.05 | 300 |

12 | 2.1±0.2 | 0.35±0.05 | 0.50±0.05 | 300 |

11 | 2.4±0.2 | 0.35±0.05 | 0.50±0.05 | 300 |

10 | 2.7±0.2 | 0.35±0.05 | 0.50±0.05 | 300 |

9 | 3.0±0.2 | 0.40±0.05 | 0.50±0.05 | 300 |

8 | 3.3±0.2 | 0.40±0.05 | 0.50±0.05 | 300 |

7 | 3.7±0.2 | 0.40±0.05 | 0.50±0.05 | 300 |

6 | 4.2±0.3 | 0.45±0.05 | 0.50±0.05 | 300 |

5 | 4.7±0.3 | 0.45±0.05 | 0.55±0.05 | 300 |

4 | 5.3±0.3 | 0.45±0.05 | 0.55±0.05 | 300 |

3 | 5.9±0.3 | 0.45±0.05 | 0.55±0.05 | 200 |

2 | 6.6±0.3 | 0.45±0.05 | 0.55±0.05 | 200 |

1 | 7.4±0.35 | 0.45±0.05 | 0.55±0.55 | 150 |

0 | 8.3±0.35 | 0.45±0.05 | 0.55±0.55 | 100 |

(Two) The British system series

Size (inch) | Inner Diameter(mm) | Wall thickness(mm) | Packing size (m/r) | |

SB-300 | SB-600 | |||

5/16 | 8.0±0.35 | 0.45±0.05 | 0.55±0.05 | 100 |

3/8 | 9.5±0.35 | 0.50±0.05 | 0.55±0.05 | 100 |

7/16 | 11.1±0.35 | 0.55±0.10 | 0.65±0.10 | 50 |

1/2 | 12.7±0.35 | 0.55±0.10 | 0.65±0.10 | 50 |

9/16 | 14.3±0.4 | 0.65±0.10 | 0.75±0.10 | 50 |

5/8 | 16.0±0.4 | 0.65±0.10 | 0.75±0.10 | 50 |

3/4 | 19.0±0.4 | 0.65±0.10 | 0.75±0.10 | 50 |

7/8 | 22.0±0.5 | 0.75±0.15 | 0.85±0.15 | 50 |

1 | 25.0±0.5 | 0.75±0.15 | 0.85±0.15 | 50 |

Dimension (Three) The British system series

Inner Diameter (mm) | Wall thickness(mm) | Packing size (m/r) | |

SB-300 | SB-600 | ||

0.80±0.1 | 0.25±0.05 | 0.40±0.05 | 500 |

1.0±0.1 | 0.30±0.05 | 0.40±0.05 | 500 |

1.5±0.1 | 0.33±0.05 | 0.45±0.05 | 300 |

2.0±0.2 | 0.33±0.05 | 0.50±0.05 | 300 |

2.5±0.2 | 0.35±0.05 | 0.50±0.05 | 300 |

3.0±0.2 | 0.40±0.05 | 0.50±0.05 | 300 |

3.5±0.2 | 0.40±0.05 | 0.50±0.05 | 300 |

4.0±0.2 | 0.45±0.05 | 0.55±0.05 | 300 |

Inner Diameter (mm) | Wall thickness(mm) | Packing size (m/r) | |

SB-300 | SB-600 | ||

4.5±0.3 | 0.45±0.05 | 0.55±0.05 | 300 |

5.0±0.3 | 0.45±0.05 | 0.55±0.05 | 300 |

6.0±0.3 | 0.45±0.05 | 0.55±0.05 | 200 |

7.0±0.3 | 0.45±0.05 | 0.55±0.05 | 150 |

8.0±0.35 | 0.45±0.05 | 0.55±0.05 | 100 |

9.0±0.35 | 0.50±0.05 | 0.60±0.05 | 100 |

10.0±0.35 | 0.55±0.10 | 0.65±0.10 | 50 |

11.0±0.40 | 0.55±0.10 | 0.65±0.10 | 50 |

12.0±0.40 | 0.55±0.10 | 0.65±0.10 | 50 |

13.0±0.40 | 0.55±0.10 | 0.65±0.10 | 50 |

14.0±0.40 | 0.55±0.10 | 0.65±0.10 | 50 |

15.0±0.40 | 0.60±0.10 | 0.70±0.10 | 50 |

16.0±0.40 | 0.60±0.10 | 0.70±0.10 | 50 |

17.0±0.40 | 0.60±0.10 | 0.70±0.10 | 50 |

18.0±0.40 | 0.60±0.10 | 0.70±0.10 | 50 |

19.0±0.40 | 0.65±0.10 | 0.75±0.10 | 50 |

20.0±0.50 | 0.65±0.10 | 0.75±0.10 | 50 |

21.0±0.50 | 0.65±0.10 | 0.75±0.10 | 50 |

22.0±0.50 | 0.70±0.10 | 0.80±0.10 | 50 |

23.0±0.50 | 0.70±0.10 | 0.80±0.10 | 50 |

24.0±0.50 | 0.75±0.10 | 0.85±0.10 | 50 |

25.0±0.50 | 0.75±0.10 | 0.85±0.10 | 50 |

26.0±0.50 | 0.85±0.10 | 0.85±0.10 | 50 |

29.5±2.0 | 2.75±0.50 | 2.75±0.50 | 25 |

Remark: Other size and color can be produced upon request.

![]()