No second Co., in China!

No second Co., in China!

No second Co., in China!

6 Purshase Reasons:

1) Complete certification, and UL full-color certification, 80% of competing products are only certified in white, so a large number of products have been eliminated.

2) UL certification has a wide range of diameters, from 0.55 to 25.4mm, and most competing products only certified 0.55 to 9.5mm.

3) Take the lead in switching to fully automatic high-speed knitting machines, 90% of the industry is still using low-speed knitting machines, and Shunbo's production capacity is three times higher.

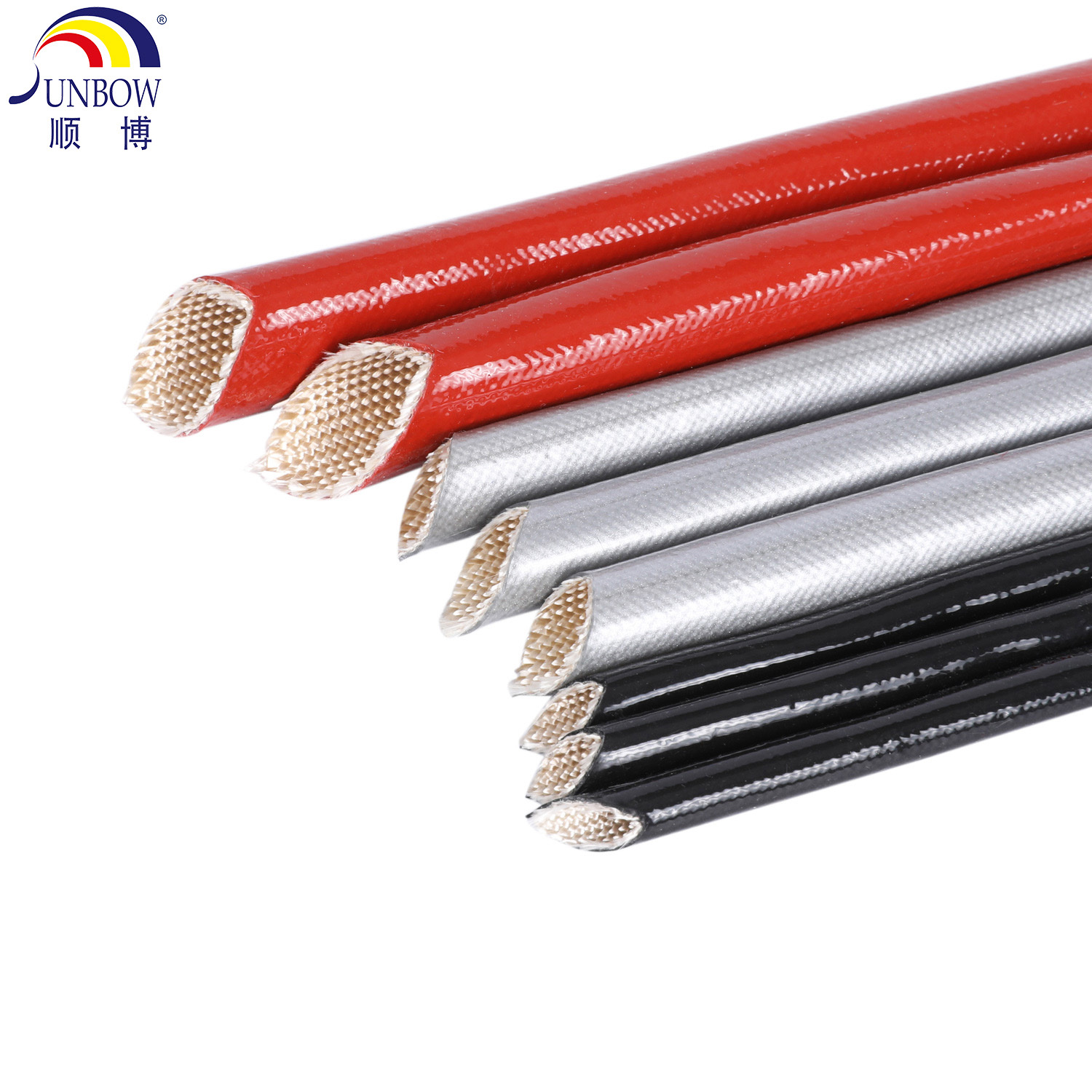

4) Double-layer glass fiber tubes, double-row glass fiber tubes, and snake skin tubes can be customized to meet customer requirements, and it is difficult to find a second supplier for high-quality competing products.

5) 99% of the proofing is passed at one time, and the time is controlled within 1~2 days. The success rate and speed basically have no rivals in China.

6) Most of the car brands you know (regardless of gasoline trucks or trams), many of them are already using our fiberglass tubes.

Model Number:SB-SGS-70

Max Temperature Rating: 200ºC, Max Working Voltage: 600V

Structure

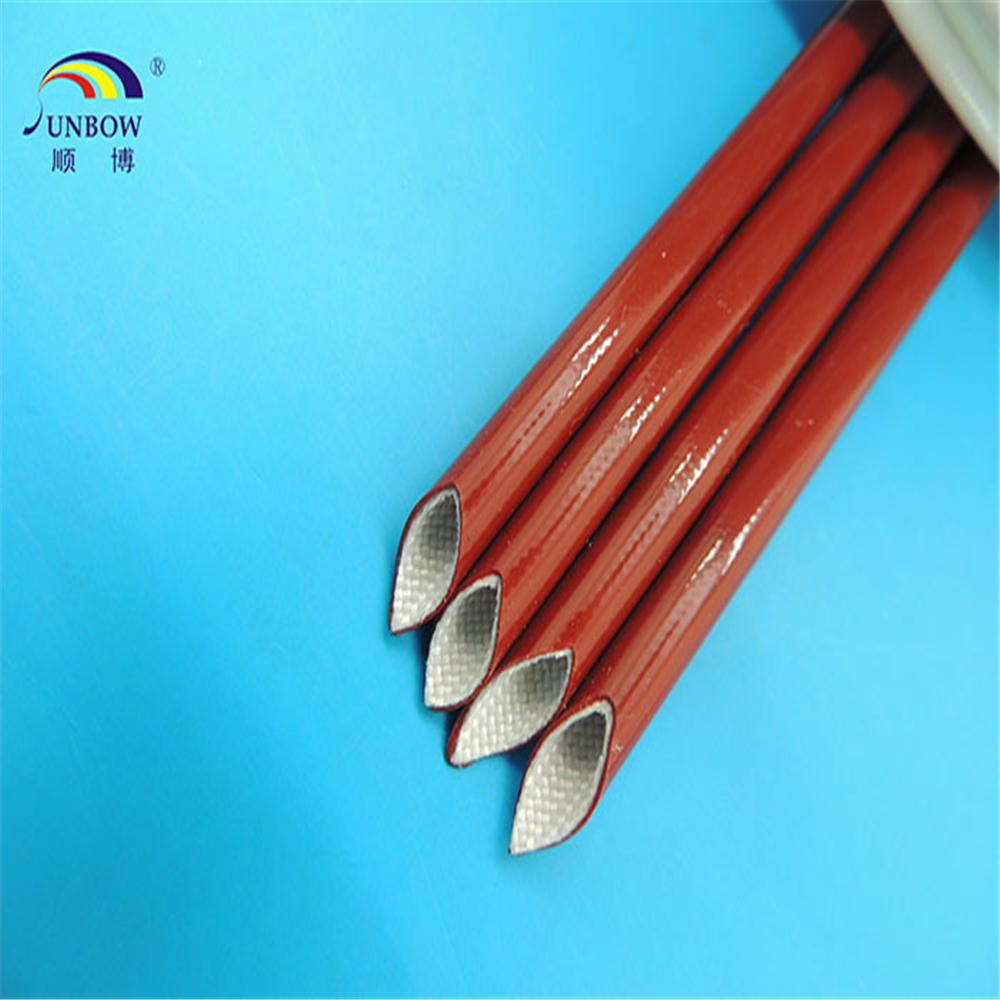

It is braided by non-alkali fiberglass, then coated with silicone resin and treated in high temperature.

Characteristics

Flammability: self-extinguishing, wear resistance, tear resistance, good compatibility with same class impregnation varnishes, good mechanical resistance, very flexible.

Application

Internal wiring of electronics, electrical appliances and automotive, classes H and C motors, transformers, generators, heating apparatus, lighting, control, inverter, etc.

Specification

Item | Performance | Note | |

Dielectric breakdown voltage KV AC | Minimum average | ≥7.0 | Before aged |

Minimum single point | ≥5.0 | ||

Minimum average | ≥3.5 | 168 HRS* 265±5ºC 265±5ºC 168HRS Aging | |

Minimum single point | ≥2.5 | ||

No breakdown | / | 1 KV IN 2% Salt water | |

Thermal endurance | No indication of crack | OK | 1440 HRS* 235±5ºC 235±5ºC 1440HRS Aging |

Fire resistance | VW-1 | OK | UL 1441 |

Dimension

Inside Diameter | Wall thickness (mm) | Standard package (m/roll) | |

Nominal (mm) | Tolerance (mm) | ||

φ0.5 | +0.2, -0.1 | ≥0.37 | 200 |

φ1.0 | +0.2, -0.1 | ≥0.37 | 200 |

φ1.5 | +0.2, -0.1 | ≥0.37 | 200 |

φ2.0 | +0.2, -0.1 | ≥0.37 | 100 |

φ2.5 | +0.3, -0.1 | ≥0.42 | 100 |

φ3.0 | +0.3, -0.1 | ≥0.42 | 100 |

φ3.5 | +0.3, -0.1 | ≥0.42 | 100 |

φ4.0 | +0.3, -0.1 | ≥0.42 | 100 |

φ4.5 | +0.3, -0.1 | ≥0.51 | 100 |

φ5.0 | +0.3, -0.1 | ≥0.51 | 100 |

φ6.0 | +0.3, -0.1 | ≥0.51 | 100 |

φ7.0 | +0.3, -0.1 | ≥0.56 | 50 |

φ8.0 | +0.3, -0.1 | ≥0.56 | 50 |

φ9.0 | +0.3, -0.1 | ≥0.66 | 50 |

φ10.0 | +0.3, -0.1 | ≥0.66 | 50 |

φ12.0 | +1.0, -1.0 | ≥0.66 | 50 |

φ14.0 | +1.0, -1.0 | ≥0.66 | 25 |

φ16.0 | +1.0, -1.0 | ≥0.66 | 25 |

φ18.0 | +1.0, -1.0 | ≥0.66 | 25 |

φ20.0 | +1.0, -1.0 | ≥0.76 | 25 |

φ25.0 | +1.0, -1.0 | ≥0.76 | 25 |

φ30.0 | +1.0, -1.0 | ≥0.76 | 25 |

Package: Packing by rolls or cut upon request.

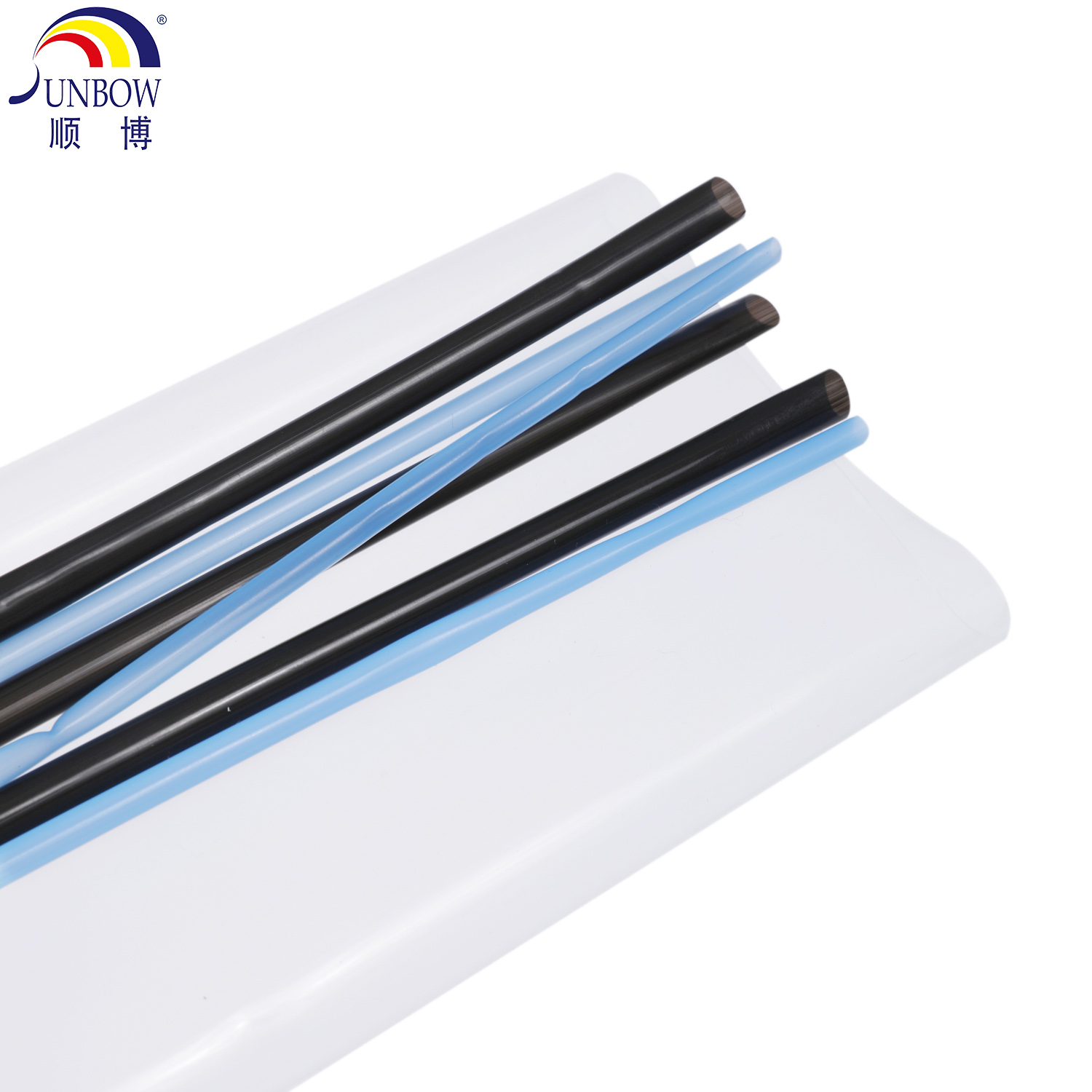

Color: Standard color is white, other color available upon request. The colors of braided can be customized.

Customer Case:

SUNBOW 3KV glass fiber casing not only matches the same 4KV, but also replaces the SG-240 of the international brand Delfingen

SUNBOW's fiberglass casing can not only achieve 3KV compared to the same 4KV, but also can replace the SG-240 of the international brand Delfingen. China is already the world's second largest economy, and the quality of domestic brands is no longer in the past. It is also the mainstay of the outstanding.

As we all know, the fiberglass casing industry is mixed. As long as the customer requires, the supplier’s breakdown voltage coefficient can be written according to the customer’s procurement requirements. For a fiberglass casing, the thickness of 2.0mm can be written in the specification. Breakdown voltage coefficient of 10KV. I can’t help asking, how ignorant and daring is it to write drawings or specifications like this?

Faced with such a situation, it is very difficult for customers to choose a suitable product of fiberglass casing, because there is no standard, no principle, and no bottom line. As a manufacturer of fiberglass sleeving, it is also miserable. It is not clear to the customers who have received the wrong information. Why is the fiberglass sleeving also called self-extinguishing pipe? The fiberglass sleeving generally only corresponds to product applications within 1.0mm. Customers have to ask you for 2.0mm thickness? How to do?

I suggest that manufacturers who purchase fiberglass sleeving should first learn about the first-line brand fiberglass sleeving from Italy, the United States, and Japan. Even if the unit price is high, you can only refer to other people’s specifications to learn about the international market of fiberglass sleeving. Technical level and standards.

SUNBOW’s fiberglass sleeve SB-SGS-30 can completely replace the SG-240 of the international brand Delfingen. The sleeve is made of self-formulated coated silicone oil, which can help customers to put on the thread easily. To better improve the accuracy and efficiency of use. The more important point is that SUNBOW’s fiberglass sleeve SB-SGS-30 can be directly used to replace the miscellaneous fiberglass sleeves on the market, and the temperature resistance can be directly increased by 40-50 degrees, which can completely solve the problem of customer’s wire harness being burned and Quality issues such as malfunctions.

SUNBOW's fiberglass sleeve SB-SGS-30 has the following advantages:

1. Using glass fiber yarn as the substrate, the coated silicone oil is a raw material imported from Germany, the product has good wear resistance and toughness, is not easy to tear, the flame retardant grade reaches VW-1, and the insulation effect is very good;

2. It can be cut into various lengths to meet the different design needs of customers;

3. Although SB-SGS-30 only has a thickness of 0.66mm, its breakdown voltage can reach 4.0KV, and it meets the UL VW-1 flame retardant and fireproof rating.

SUNBOW's fiberglass bushing SB-SGS-30 is mainly used in the fields of wiring harnesses for household appliances, transformers, inverters, industrial motors, new energy vehicles, power tools, motors, and power semiconductors.