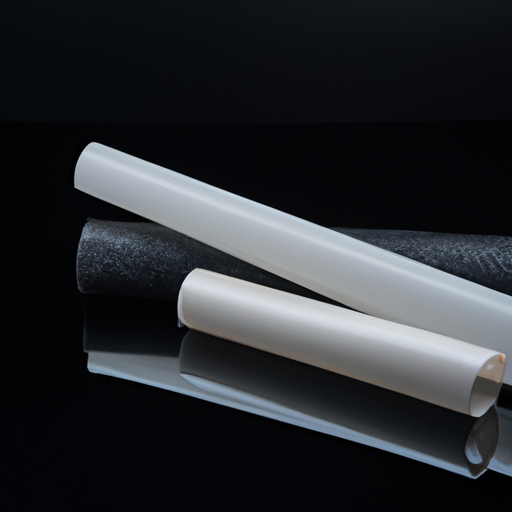

Silicon resin glass fiber sleeve is a versatile and durable product that is used in a variety of industries for insulation and protection purposes. In order to ensure the quality and performance of this product, there are certain product standards that must be met. These standards are put in place to guarantee that the silicon resin glass fiber sleeve is safe, reliable, and effective for its intended use.

In addition to the material composition, the thickness of the silicon resin glass fiber sleeve is also an important product standard. The sleeve should have a uniform thickness that provides adequate insulation and protection for the components it covers. A thicker sleeve will offer better insulation properties and increased durability, while a thinner sleeve may be more flexible and easier to install.

Another product standard for silicon resin glass fiber sleeve is its temperature rating. The sleeve should be able to withstand high temperatures without degrading or melting, in order to protect the components it covers from heat damage. The temperature rating of the sleeve should be clearly marked on the product packaging, so that users can easily determine if it is suitable for their specific application.

In addition to temperature resistance, the silicon resin glass fiber sleeve should also have good electrical insulation properties. This is essential for protecting wires and cables from electrical hazards, such as short circuits or electrical fires. The sleeve should be able to provide a high level of insulation to prevent electrical current from leaking or arcing, which could cause damage to the components it covers.

Durability is another important product standard for silicon resin glass fiber sleeve. The sleeve should be able to withstand repeated bending, twisting, and stretching without tearing or breaking. It should also be resistant to chemicals, oils, and other substances that could cause it to deteriorate over time. A durable sleeve will provide long-lasting protection for components and reduce the need for frequent replacements.

In addition to these product standards, silicon resin glass fiber sleeve should also meet industry-specific requirements and regulations. For example, sleeves used in the aerospace industry may need to meet certain specifications for flame resistance and smoke emissions, while sleeves used in the automotive industry may need to meet specific standards for temperature resistance and mechanical strength.

Overall, silicon resin glass fiber sleeve is a high-quality product that offers excellent insulation and protection for a wide range of applications. By meeting product standards for material composition, thickness, temperature rating, electrical insulation, durability, and industry-specific requirements, this sleeve can provide reliable and effective protection for components in various industries. When choosing a silicon resin glass fiber sleeve, it is important to look for products that meet these standards to ensure optimal performance and safety.